I woke up at 3 am today. This is early, even for me. I've been having some tendonitis in my left arm lately, and I forgot to take some Advil before I went to bed. I must have laid on my arm because it was sore and woke me up.

The workday started with a visit from the warranty representative of our builders to start the drywall repair. He came and went throughout the day applying a coat of mud and sanding it when it was dry. He has to come back next week to finish the mud job and apply paint.

Dad came by around nine o'clock. He started driving some screws on the deck when I wasn't looking.

We started on the bump-out and worked our way out. After attaching several planks, we found that we were one 20' plank short. Ugh. The one remaining 20 footer was pretty scratched up, so I figured that I would exchange it. I looked at putting it in or on top of the mini-van, but the board was longer than the van and too flexible to go on the roof. I called the lumberyard

A. D. Moyer where I purchased the material to see if it would be possible to get a late day delivery and exchange. Frankly I didn't think that it was going to happen. At four o'clock the truck rolled up and dropped off the material - at no charge. Awesome customer focus!

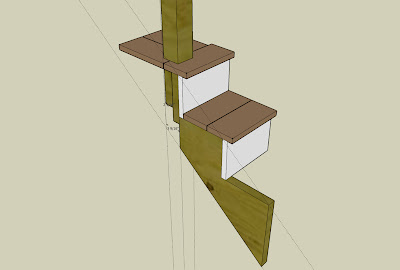

While we waited for the material to finish up the bump-out, we moved to the house side and wrapped up the inside 2 foot section. There was some cutting and tweaking involved, so we took our time here. Once we got this section done, we started trimming the board edges with the circular saw. Fortunately I noticed that one CONCEALoc fastener was hanging slightly over the edge of the joist before I started cutting. This would have wrecked the circular saw blade I had just purchased to cut the deck edges. I had to attack this with a jig-saw and a metal cutting bit. Actually 2 metal cutting bits, the fasteners are pretty tough stuff.

Mid afternoon we had a rainstorm which had us clear everything off the deck. The rain lasted 10 minutes, then the sun came out again. We were able to get back to work shortly after it stopped.

Tomorrow we will attach the last three planks, trim the edges, and start with the Radiance Rail sections. There are 12 sections of railing that will need to go up.

We had a scheduled visit from the plumbing company to fix a problem with the master bath tub. When the master toilet was flushed, it would suck the water out of the tub's drain line and allow septic gases into the house. It turns out that it was plumbed wrong and didn't vent the tub properly. Unfortunately, they had to cut several holes in our kitchen ceiling to fix the problem. The builder's handyman will be coming next week to do the drywall. This is going to be a tough drywall job as it is in the kitchen ceiling and will be easily seen if not done well.

We had a scheduled visit from the plumbing company to fix a problem with the master bath tub. When the master toilet was flushed, it would suck the water out of the tub's drain line and allow septic gases into the house. It turns out that it was plumbed wrong and didn't vent the tub properly. Unfortunately, they had to cut several holes in our kitchen ceiling to fix the problem. The builder's handyman will be coming next week to do the drywall. This is going to be a tough drywall job as it is in the kitchen ceiling and will be easily seen if not done well.